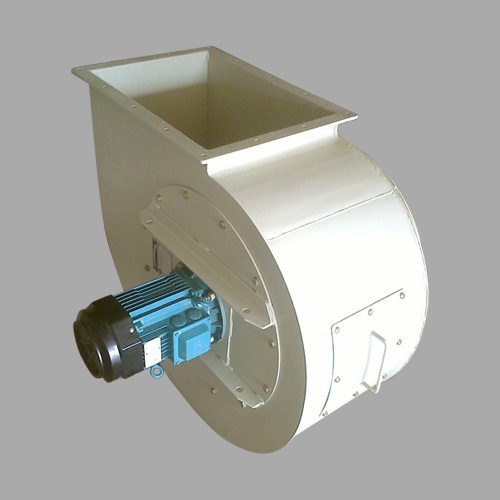

Fume Extraction System

Price 750000 INR/ Unit

MOQ : 1 Piece

Fume Extraction System Specification

- Size

- Standard

- Blade Material

- Aluminum

- Type

- Fume Extraction System

- Installation Type

- Floor Mounted

- Power

- 2 HP

- Power Source

- Electric

- Voltage

- 220-415 V

- Energy Efficiency Rating

- A++

- Speed Mode

- Single

- Blade Diameter

- 24 inch

- No. Of Blades

- 8

- Color

- Grey

- Material

- Mild Steel

- Remote Operated

- No

Fume Extraction System Trade Information

- Minimum Order Quantity

- 1 Piece

- FOB Port

- CHENNAI

- Supply Ability

- 1 Piece Per Week

- Delivery Time

- 1-2 Week

- Sample Policy

- If order is confirmed we will reimburse the sample cost

- Packaging Details

- Wooden Crate

- Main Export Market(s)

- Australia, Middle East, Africa, Asia

- Main Domestic Market

- All India

About Fume Extraction System

People install this Fume Extraction System in the industrial units to extract toxic & corrosive gas and airborne particles. The system utilizes compressed air to perform dust extraction and then automatically lower into the mobile dust collector. Dust lowering in the container makes the disposal of particulate matter in a safe and hygienic manner. Installation of this system results in reducing health problems and accident risks due to the presence of hazardous pollutants in the atmosphere. Owing to its high efficiency and minimum power consumption, the system is installed in chemical processing, metalworking, manufacturing and woodworking industries. Fume Extraction System is meticulously examined on some essential parameters like longevity, extraction efficiency, overall power consumption rate, etc.

Efficient Multi-stage Filtration

Equipped with a pre-filter, HEPA filter, and carbon layer, the fume extraction system provides superior air purification by capturing particulates, smoke, and odors. This layered approach makes it suitable for diverse industrial and laboratory applications, ensuring cleaner air and promoting a healthier working environment.

Powerful and Quiet Operation

Driven by a 2 HP electric motor, the system delivers strong airflow while maintaining noise levels under 70 dB. Its precision-engineered 8-blade aluminum fan ensures optimal ventilation, making it ideal for continuous industrial or laboratory use without causing acoustic discomfort.

Mobility and Ease of Installation

This floor-mounted fume extractor is portable, featuring castor wheels for easy relocation. The standard size and robust mild steel housing enable quick installation in various workspaces, while manual control systems allow direct adjustment and straightforward maintenance.

FAQs of Fume Extraction System:

Q: How does the multi-stage filtration in the fume extraction system improve air quality?

A: The system uses a series of filters, including a pre-filter, HEPA filter, and activated carbon, to capture different types of contaminants. This design ensures particulate matter, chemical vapors, and odors are efficiently removed, resulting in cleaner, safer air within your facility.Q: What applications are suitable for this fume extraction system?

A: This fume extraction system is ideal for industrial processes like welding, soldering, and laboratory work where airborne particulates and fumes are generated. It provides effective air purification in manufacturing, fabrication, research labs, and similar environments.Q: When should the filters be replaced in the fume extraction system?

A: Filter replacement frequency depends on usage intensity and contaminant load. Generally, pre-filters may need monthly checks, HEPA filters every 6-12 months, and carbon filters based on odor detection or every 6-12 months as well. Always follow manufacturer guidelines for optimal performance.Q: Where should the fume extraction system be installed for best results?

A: Install the unit close to the source of fume generation, ensuring that the 150 mm duct can directly access the contamination zone. Its floor-mounted, portable design with castor wheels allows for flexible placement in industrial or laboratory spaces.Q: What is the process for operating the fume extraction system?

A: Operation is straightforward with its manual control system. Once installed and connected to a power source (220-415 V), simply switch the unit on, and it will begin drawing fumes through its multi-stage filters for purification.Q: How does the system benefit users during welding and soldering activities?

A: By efficiently capturing and filtering hazardous fumes, the system helps protect users from respiratory risks, reduces maintenance from particulate build-up, and ensures compliance with workplace safety standards.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Centrifugal Fan And System Category

Commercial Centrifugal Fan

Price 50000 INR / Piece

Minimum Order Quantity : 1 Piece

Warranty : 1 year

Power Source : Electrical

Material : Metal

No. Of Blades : 1236

Centrifugal Fan

Price 25000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Warranty : 1 year

Power Source : Electrical

Material : Metal

No. Of Blades : 1236

Industrial Centrifugal Fan

Price 50000 INR / Piece

Minimum Order Quantity : 1 Piece

Warranty : 1 year

Power Source : Electrical

Material : Metal

No. Of Blades : 1236

Fume Exhaust System Fans

Price 500000 INR / Inch

Minimum Order Quantity : 10 Units

Warranty : Yes

Power Source : Electrical

Material : Stainless Steel

Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese